Stainless Steel Coil

Stainless Steel Coil

317L Stainless Steel Coil

317L stainless steel is a lower carbon version of 317 stainless steel, which means it has better corrosion resistance and higher creep strength at high temperatures. It contains molybdenum, nickel and chromium as main alloying elements.

Big fire special steel, high strength steel plate, steel industry supply and demand, steel suppliers

317L Stainless Steel Coil Description

317L is a low-carbon austenitic stainless steel containing molybdenum. More chromium, nickel and molybdenum are added to obtain better corrosion resistance and increase the resistance to sulfurous acid, acetic acid, formic acid, citric acid and tartaric acid. Resistance to chemical attack. Due to its low carbon content, 317L also provides resistance to sensitization during welding, as well as higher creep, rupture stress and high temperature tensile strength. It is non-magnetic in the annealed state, but may become slightly magnetic after welding.

Product Parameters

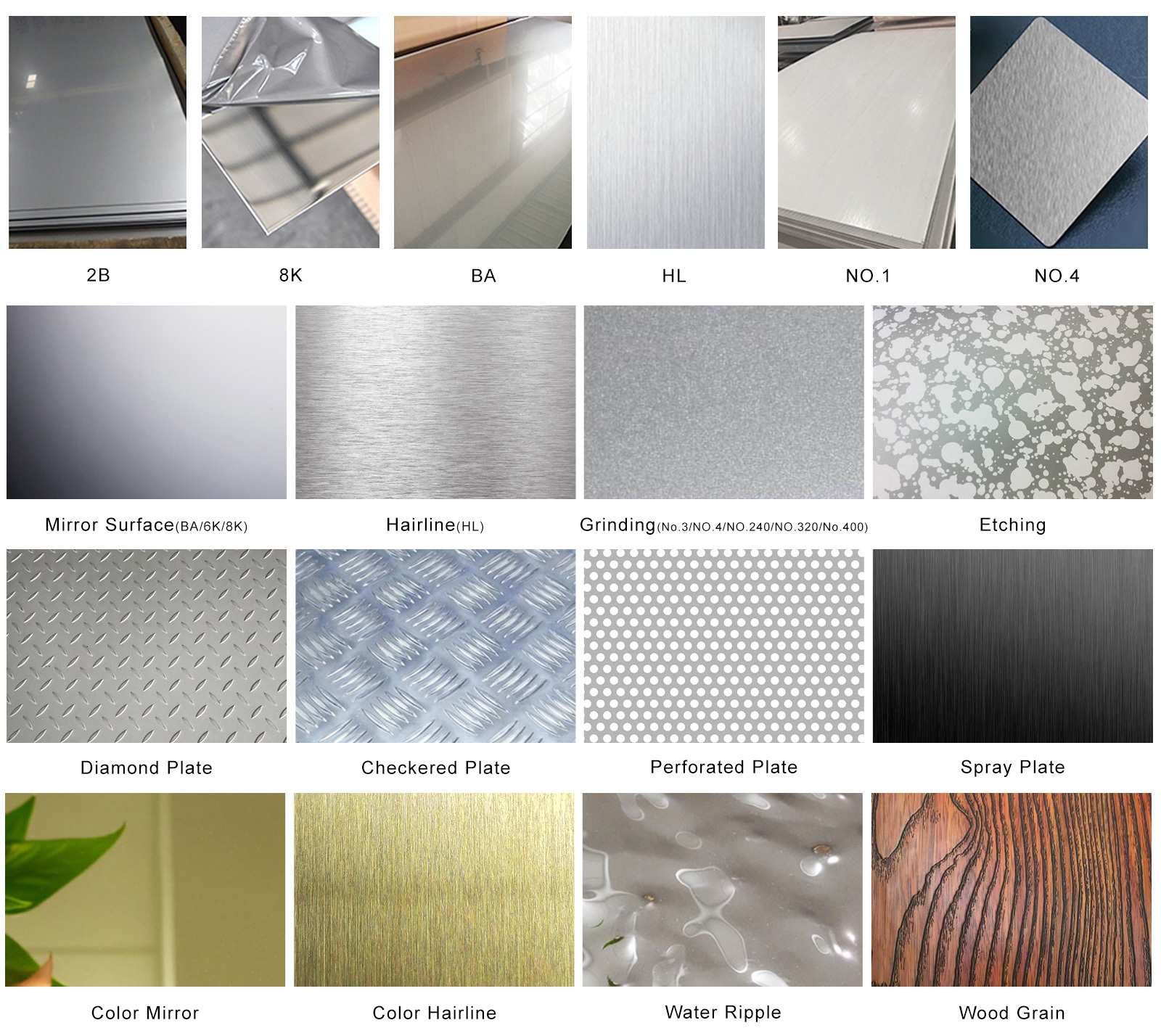

Product Name 317L Stainless Steel Coil Type Steel Coil Thickness 2.5mm-10.0mm Length 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. Width 610mm-2000mm Standard ASTM, AISI, JIS, GB, DIN, EN, etc. Surface BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. Scope of Application Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. Certificate ISO, SGS, BV, etc. Production Technology Hot Rolling, Cold Rolling Edge Processing Edging, Trimming

Chemical Composition

C Si Mn Cr Ni S P Mo ≤ 0.035 ≤ 0.75 ≤ 2.0 18.0~20.0 11.0~15.0 ≤ 0.03 ≤ 0.04 3.0~4.0

Mechanical Properties

Tensile Strength Kb (MPa) Yield Strength σ0.2 (MPa) Elongation D5 (%) Hardness ≥480 ≥177 ≥ 40 ≤ 187HB;≤ 90HRB;≤ 200HV

Physical Performance

Density(g/cm³) Modulus of Elasticity(Gpa) Coefficient of Thermal Expansion(10-6/°C) Coefficient of Thermal Conductivity(W/m*K) Resistivity(ΜΩ. cm) 7.99 193 16.0 16.2 79

Surface Selection

What is your working time?

In general, our online service time is Beijing time: 8:00-22:00, after 22:00, we will reply to your inquiry during the next working day.

How to pack the products?

The inner layer has a waterproof paper outer layer with iron packaging and is fixed with a fumigation wooden pallet. It can effectively protect products from corrosion during ocean transportation.

Can you send samples?

Of course, we can send samples to all parts of the world, our samples are free, but customers need to bear the courier costs.

What product information do I need to provide?

You need to provide the grade, width, thickness, coating and the number of tons you need to purchase.

What are the shipping ports?

Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can choose other ports according to your needs.

About product prices?

Prices vary from period to period due to cyclical changes in the price of raw materials.

What are the certifications for your products?

We have ISO 9001, SGS, EWC and other certifications.

How long does your delivery time take?

In general, our delivery time is within 30-45 days, and may be delayed if the demand is extremely large or special circumstances occur.